Introduction

Bond-Ply LMS-HD (Laminate Material-Silicone, High Durability) is a thermally conductive

cured core reinforced high performance laminate, which requires heat to cure and bond.

The low modulus silicone design effectively absorbs mechanical stresses induced by assembly-level

coefficient of thermal expansion mismatches. This application note will provide recommendations

for the preferred handling, fixturing and laminating methods and procedures for producing a high performance laminate utilizing BOND PLY TBP 1400LMS-HD

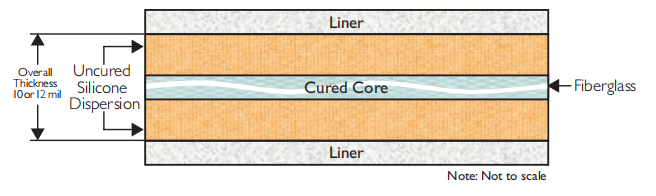

Material Characteristics Bond-Ply LMS-HD is supplied as an uncured (B-stage or green state) material

with a continuous liner on either side. See diagram below.

When designing an application for BERGQUIST Bond-Ply LMS-HD, the flatness, co-planarity and surface finish of the application

surface should be well understood. The 12 mil thickness of Bond-Ply LMS-HD will allow for more coplanar mismatches than the 10 mil.

Cure Profiles

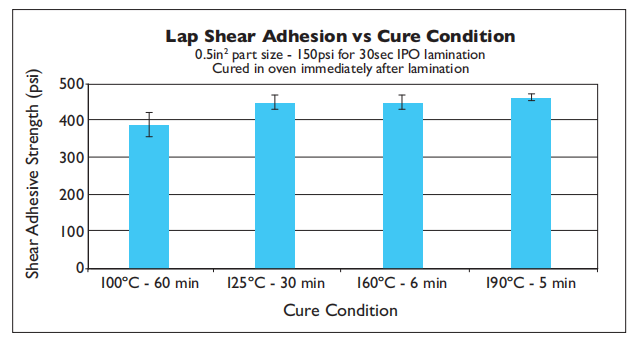

BERGQUIST Bond-Ply LMS-HD can be cured at various temperature conditions. A typical cure profile is 160°C for 6 minutes at the interface.

Once the temperature of the LMS-HD (interface) has reached 160°C, the clock starts and after 6 minutes the LMS-HD is fully cured.

Below is the typical lap shear values (aluminum to aluminum) that can be achieved at various cure profiles.

Fixturing

There is no one correct method or set of parameters to laminate Bond-Ply LMS-HD for all applications.

The optimal lamination conditions are application specific. A relatively large lamination pressure (up to 200 psi)

can be applied when there is a low potential of reducing the dielectric integrity of the cured core.

High lamination pressure produces high lap shear values and better thermal performance.

Each application should be reviewed by the customer to determine the appropriate lamination process (pressure and dwell time) and setup on application specific requirements.

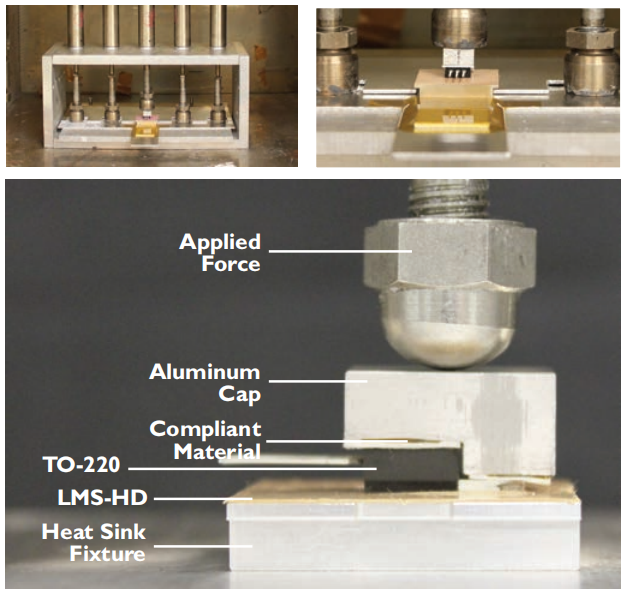

Constant Pressure Fixturing

In cases where there is concern that the component may move or shift after lamination and prior to cure,

Bond-Ply LMS-HD can be laminated utilizing a fixture that applies pressure to the assembly (heat generating device, LMS-HD, heatsink)

through the entire lamination process. This method ensures that there is no movement of the assembly during processing.

This method requires the heating of both the assembly and fixture, which adds time and utilizes additional energy.